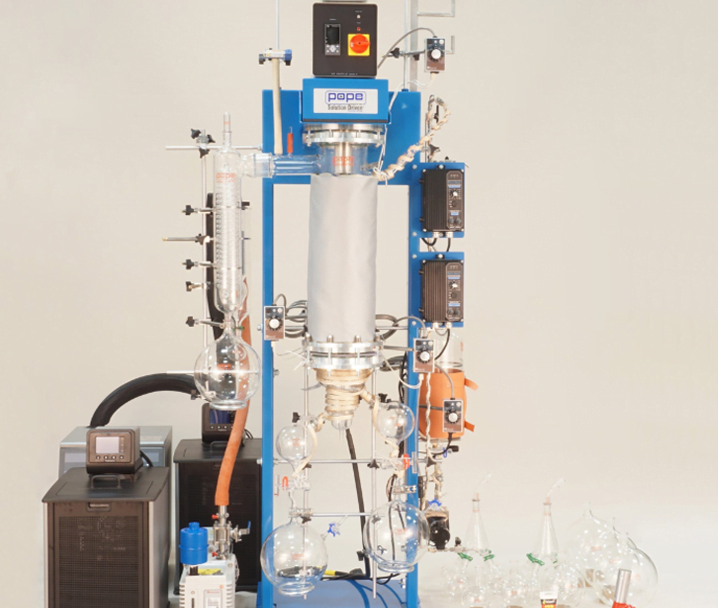

The Short path distillation unit is a highly efficient purification method ideal for laboratory use where limited space is a concern. It operates under low pressure and involves the use of several flasks with short extraction pathways to separate the condensed material, with a maximum length of a few centimeters. Unlike traditional path distillation techniques that require larger equipment to achieve desired purity levels, short path distillation can reach up to 99% purity using fewer components in a compact working area.

-

E-mail sales@thermosag.com

-

Mobile no. +91 91042 11441