Features of Hydrocyclone Filter Offered by Thermosag

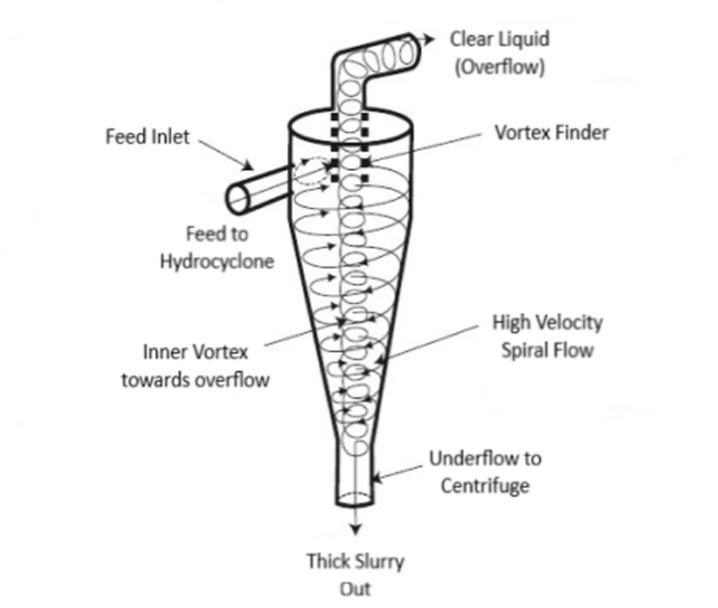

Cyclones are composed of four main components: the feed chamber, the cone (body), the underflow (spigot liner or apex), and the overflow (vortex finder). The feed chamber directs the slurry into a spiral flow, generating a vortex. The cone (body), which can be a single piece or multiple pieces, allows the material to continue to spiral, generating a centripetal force that pushes coarse material outwards, allowing fine particles and most of the water to move upward in a vortex.

The fine particles leave the cyclone through the overflow, located at the top of the cyclone, while the underflow, at the bottom of the cyclone, is where coarse material exits. The spigot liner, which is the underflow liner, and the open diameter of the spigot liner, along with the vortex finder, determine the mass split. Other factors affecting the separation point include feed pressure, feed density, cone length, and cone angles, in addition to the vortex finder and spigot liner.