Benefits Of Industrial MVR Mechanical Vapour Recompression

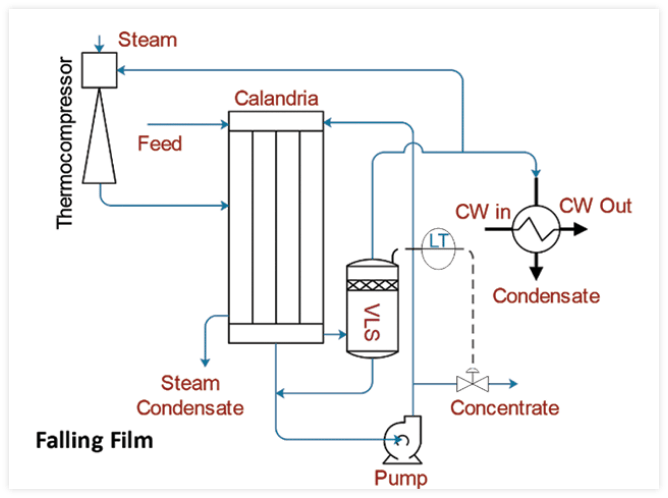

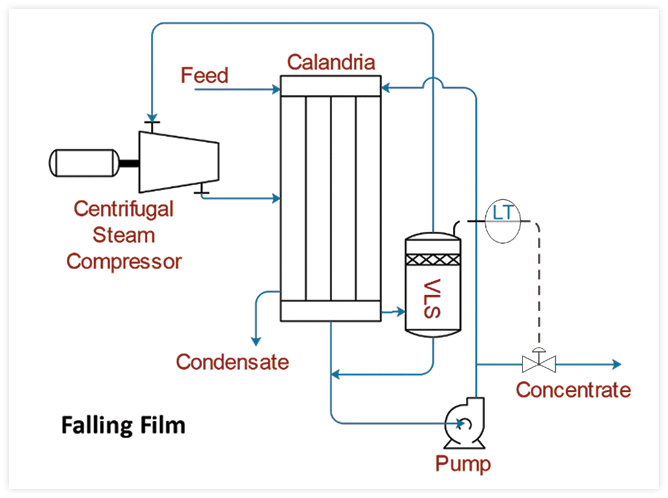

The main benefit of MVR mechanical vapour recompression is that it allows for significant energy savings. Mechanical vapour compression, unlike the alternative thermal vapor compression, does not depend on large quantity of steam supply. And since no fluid mixing occurs, all of the available vapor can be compressed for complete energy recovery.

Mechanical vapour recompressors cost a little higher than a conventionally heated thermal plant of the same capacity; however, it turns out to be a beneficial investment, in the long run, paying back investment with a plethora of benefits. The investment costs get repaid in a short period in terms of energy saving itself apart from other benefits.

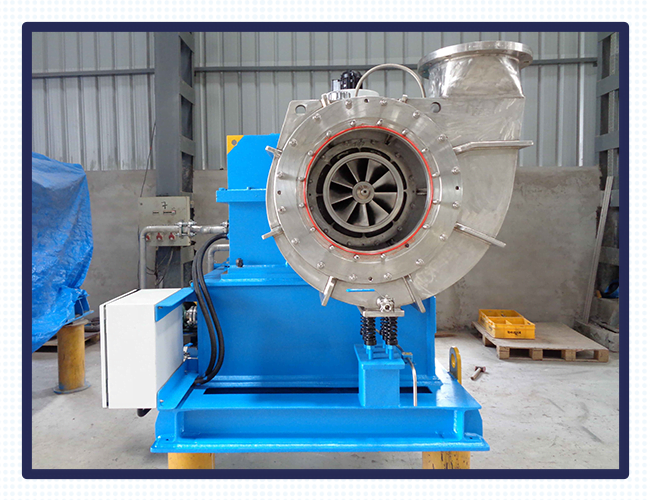

Thermosag’s centrifugal turbo recompressors remain a cut above the rest in terms of investment viability, productivity, and energy savings. This compressor is not only suited to variegated applications in various industries including (but not limited to) chemical, organic natural product production and food & beverage, but is also capable of achieving high temperature increases with sheer ease like Zero Liquid Discharge and Salt Recovery Plants.

A centrifugal turbo recompressor that operates under the mechanical vapour recompression principle also empowers your systems to achieve high temperature increases compared to any other type of Mechanical Vapour Compressor including Centrifugal Fan or Blower or Turbo Blower. Centrifugal Turbo Compressors offer exceptional energy efficiency with highest level of reliability.

Being a reputed MVR and Evaporators manufacturer supplier, one of the outstanding features of Thermosag’s centrifugal turbo compressor is its highly advanced design with latest tools and manufactured with extremely high precision.

Besides, the impeccable and wear-resistant impeller design facilitates better erosion resistance. Centrifugal turbo recompressors indeed are an ideal choice with an edge over other MVR technologies.