One-Stop Shop for Turnkey Solutions

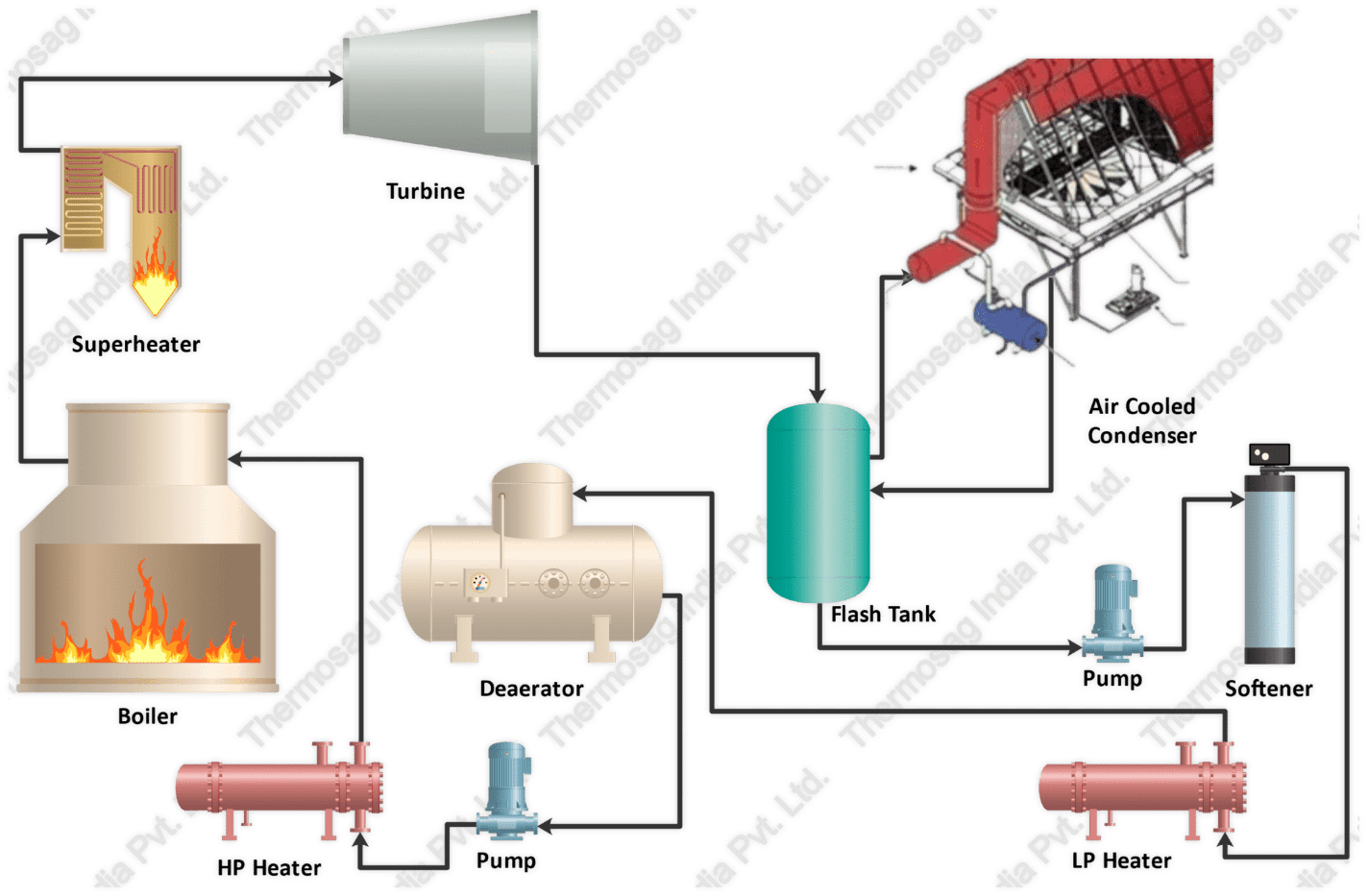

If you are looking for reliable Air-Cooled Steam Condenser manufacturers in Gujarat, India that produce less noise, emit less CO2, or that provide the highest possible energy efficiency, be sure to explore our Air-Cooled Steam Condenser for the power industry.

We are one of the eminent air-cooled steam condenser manufacturers in India All our products are tailored and delivered turnkey, making them the solution of choice for waste-to-energy, biomass plants and chemical plants.

Thermosag is committed to providing superior quality and high-performing Air-cooled Condensers. These exceptional solutions are the culmination of extensive research and development and can be customized to operate across a broad range of industries, including petroleum, power utilities, steel, cement, sugar, chemicals, and gas-processing sectors. We take pride in our product’s reliability and performance, which are a testament to our unwavering dedication to quality

At Thermosag, we adhere to the highest standards for quality and performance. We achieve these high standards by controlling the entire manufacturing process, producing all components and parts in-house, and utilizing advanced machinery in our state-of-the-art manufacturing plants. Our advanced production techniques ensure the quality our clients have come to expect from us. By maintaining complete control over the manufacturing process, we can guarantee that our Air-cooled Condensers meet and exceed the highest industry standards