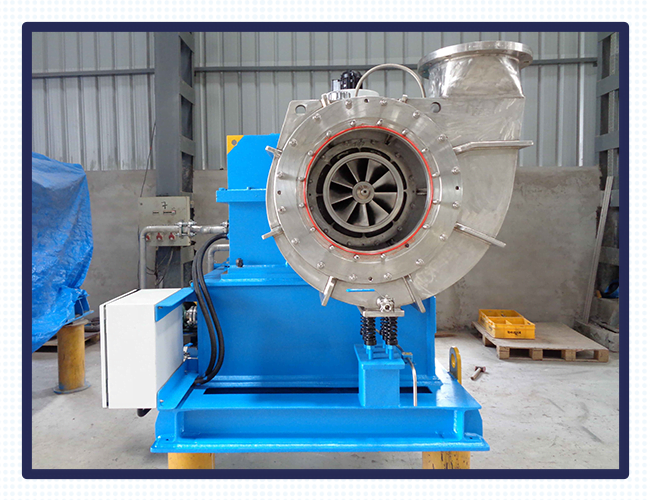

Thermosag is a leading mechanical vapor recompression (MVR) manufacturer in India, specializing in providing innovative and efficient solutions for thermal separation processes. With a focus on energy efficiency and environmental sustainability, Thermosag has established itself as a trusted name in the industry.

What is Mechanical Vapour Recompression?

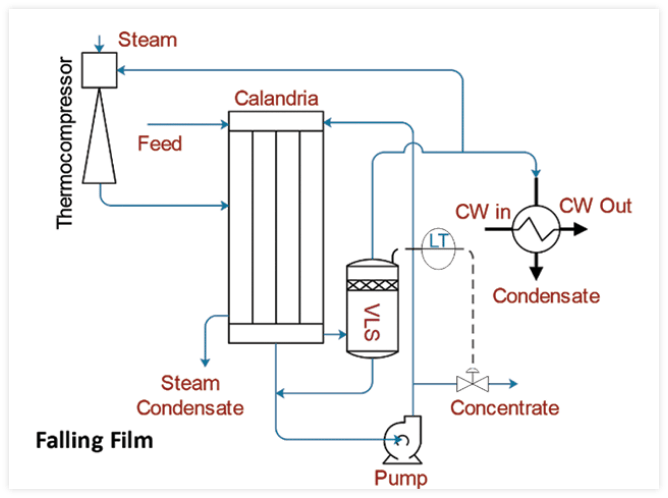

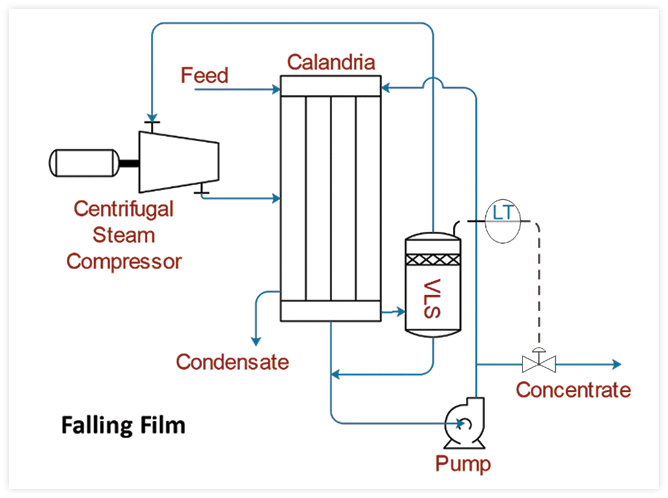

As the name suggests, mechanical vapor recompression technology involves the use of a mechanical compressor that recompresses the vapor of an MVR evaporator to a higher pressure. It functions as a heat pump, adding more energy and increasing the temperature gradient to the vapor.

Our technology offers a whole gamut of benefits ranging from reduced specific energy consumption, low operational costs, seamless evaporation of the product owing to low-temperature differences, simplicity of the process, and top-notch partial load behaviour.